Metal mesh cladding

All About Metal Mesh Cladding

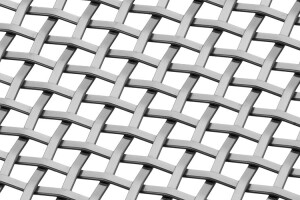

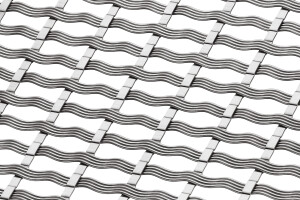

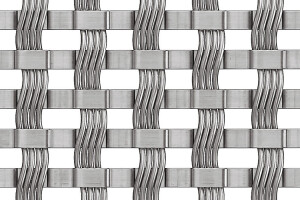

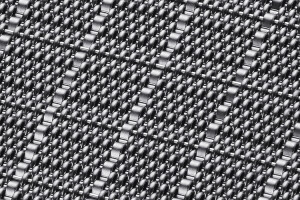

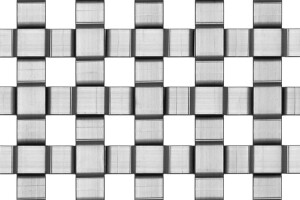

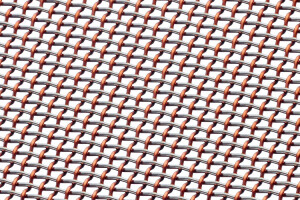

Cladding refers to components that are attached to the primary structure of a building to form an external surface that is non-structural. Cladding is normally installed to protect the material underneath from environmental element as well as normal wear and tear. Metal mesh cladding can also create unique design effects. Metal mesh cladding can be laid horizontally, vertically or diagonally as per the need of the consumer. There are several metals that are used to make this type of cladding like zinc, aluminium, steel and copper. These can be coated for extra protection.

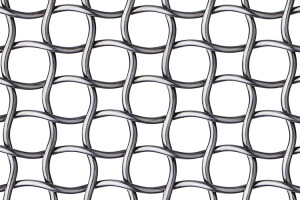

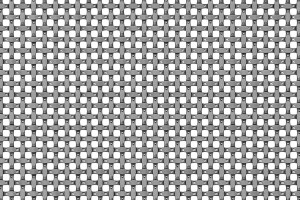

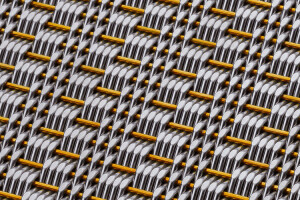

Metal mesh cladding can enliven a building which is otherwise a mere rectangular structure. Metal mesh is very versatile in nature i.e. can be easily bent and adapted to different shapes as per requirement. Metal mesh cladding is highly durable and can withstand harsh weather better than most other cladding types. The amount of light the consumer needs to pass through the cladding can be adjusted by adjusting according to the size of the mesh. Metal mesh is considered to be completely recyclable and can be easily attached to any existing system or other type of cladding.

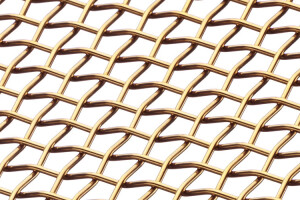

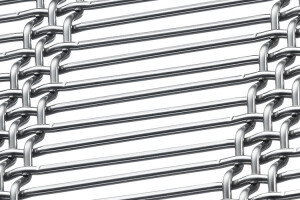

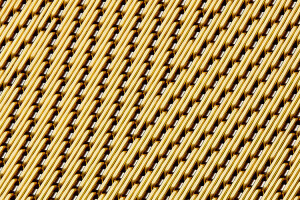

There are several types of metal meshes cladding available in the market. These are – titanium cladding, bronze cladding, brass cladding, copper cladding, zinc cladding, aluminium cladding and galvanized steel cladding. Further, consumers can control the size of the mesh as well as colour and colour combinations - which are nearly endless. Metal meshes cladding offers a great aesthetic value to the consumer. Being available in innumerable shapes, sizes, finishes and geometric patterns, metal mesh cladding is a great aesthetic addition to the building. Further, they allow the occupants to have great exterior view and plenty of natural light without disturbing privacy.

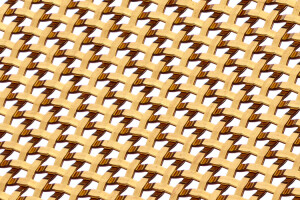

Fitting and repairing a metal mesh cladding is the job of an expert. While repairing, special care needs to be taken with respect to elements such as membranes, joints and air-tightness liners. These are easy to maintain and have a life in excess of twenty years. The surface area should be checked once a year to check if there is any dirt build-up. In case of a dirt build-up, the surface needs to be cleaned for increasing its longevity. Detergent can be used in limited quantity to clean the area effectively.

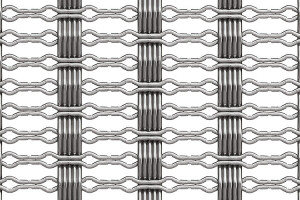

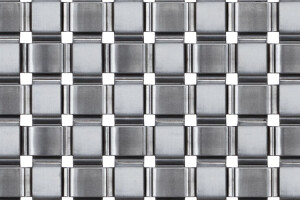

Manufacturer Spotlight: Banker Wire

Founded by Charles Banker in 1896, Banker Wire is a famous cladding manufacturing brand and is the world’s largest manufacturer of woven and welded wire mesh for architectural and industrial applications. They are also known for providing custom solutions regarding wire mesh to their customers. Modern and productive, they believe in three key mantras – Quality, Efficiency and Value.

The best Metal Meshes Cladding brands on Archello

Whether you are an architect or engineer, contractor of builder, we invite you to explore our product selector to be inspired and supported in specifying Metal Meshes Cladding in your next project.