Sollertia’s Textile Architecture Embraces the Symbiotic Relationship Between Art and Science

Sollertia, a firm specializing in textile architecture and the design, fabrication, and construction of lightweight tensile structures, is proud to extend its innovative services and expertise to Canadian architects across the country. Backed by an experienced team of professionals who specialize in high performance technical textile structures, Sollertia’s comprehensive service offering focuses on the creation of bold, durable, and innovative solutions that are advancing the state-of-the-art in architecture.

“Textile architecture is an underutilized architectural innovation in Canada, and it still isn’t taught in schools despite being an important contribution to the construction process,” notes Claude Le Bel, Founder and President of Sollertia. “Architectural textile membranes are high-performance construction materials, comparable to traditional materials, yet with a totally different design language.”

Textile Architecture 101

Tensile architecture is ideal for multiple applications, both internal and external, from acoustic and lighting solutions, to ceilings, walls, protective roofing, and more. The goal with all of these various types of projects is to create as light a product as possible. The membranes play a structural role and can be used to cover huge surfaces without the necessity of a multitude of different types of supportive materials. The lightness of a membrane, combined with its transparent nature, creates an innovative avenue for environmentally sensitive projects. For example, architectural membrane meshes can be engineered to form translucent façades, enabling infusions of light and controlling solar gains. Lightweight, yet durable, high-performance membranes provide exceptional strength and flexibility and are designed to withstand the toughest elements of the Canadian climate.

Founded in 2000, Sollertia opened its own state-of-the-art confectioning workshop in 2017. The facility is conducive to both developing innovative ideas, and to ensuring consistent quality control over the entire production process of its prefabricated membrane designs. Membranes used in textile architecture typically fall into five categories, including polyester woven with PVC coating (polyvinyl chloride), glass fiber woven with PTFE coating (polytetrafluoroethylene), ETFE film (ethylene tetrafluoroethylene), silicone coated fiberglass woven, and PTFE expanded woven with PTFE coating (Tenara).

“Technical textile membranes can be engineered for permanent, temporary, or even nomadic structures,” explains Nathalie Lortie, Director, Design and Innovation at Sollertia. “They are customizable to provide coverage over expansive surface areas, in a variety of geometric forms, and that unlocks the door to unprecedented freedom of architectural expression.”

Biodome – Raising the bar to new heights

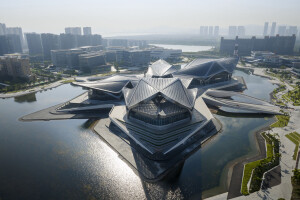

No project more thoroughly incorporates the complexity of Sollertia’s specialized expertise than the firm’s commission as part of a major renovation of Montreal’s Biodome, a science museum immersing visitors in a diversity of delicate ecosystems. While the demands of the project pushed the firm to its limits, Sollertia rose to meet every challenge head on, and to expand the boundaries of their discipline. The project’s scale of complexity drew on multiple areas of expertise, and Sollertia embarked on a journey to design and install membranes to form the facility’s transit corridors and transition spaces between the various ecosystems. Drawing upon past experiences working on projects facilities in the Biodome’s surrounding Olympic complex, the Sollertia team developed a series of different prototypes before working closely with KANVA, lead architects of the project, to select the perfect balance of materiality, flexibility, and durability for the project.

“The success of a lightweight fabric structure project such as this one requires a symbiotic relationship between architecture and engineering in order to obtain the desired aesthetics, stability, durability, and lightness as a whole,” explains Ms. Lortie. “This synergy must not only exist at the level of our very own multidisciplinary team, but also with all of the professionals and the various trades working alongside us.”

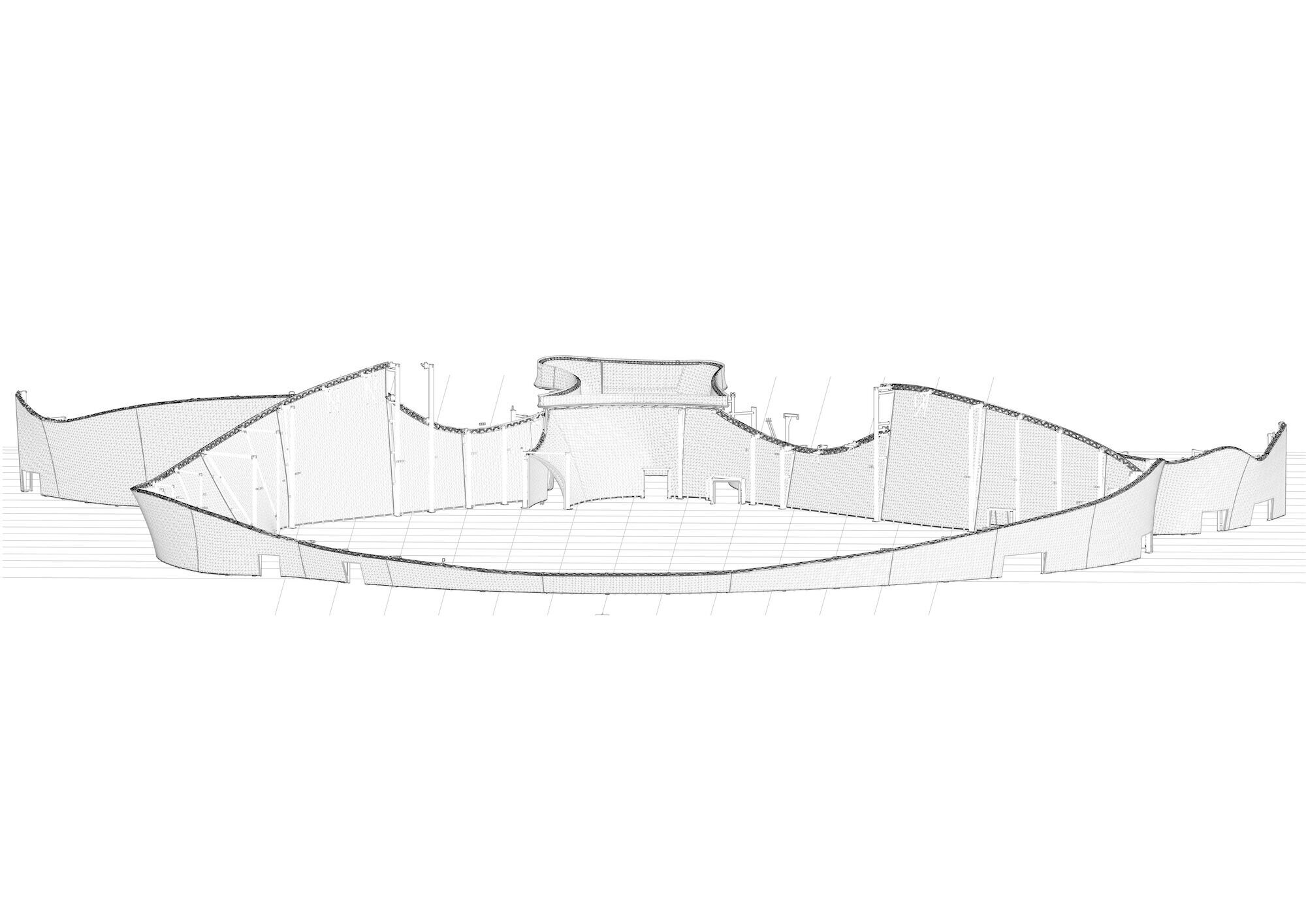

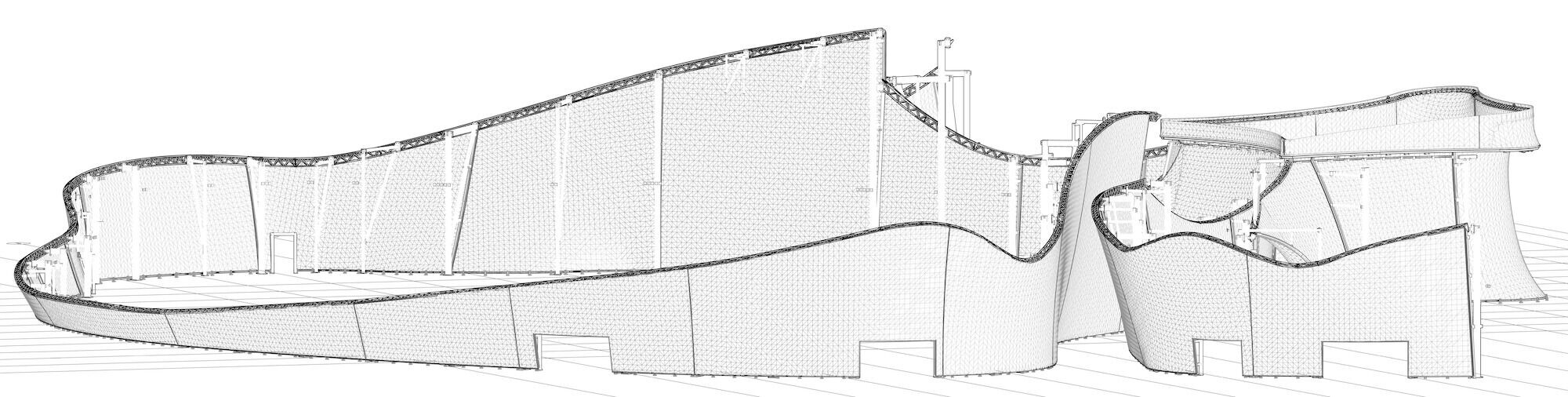

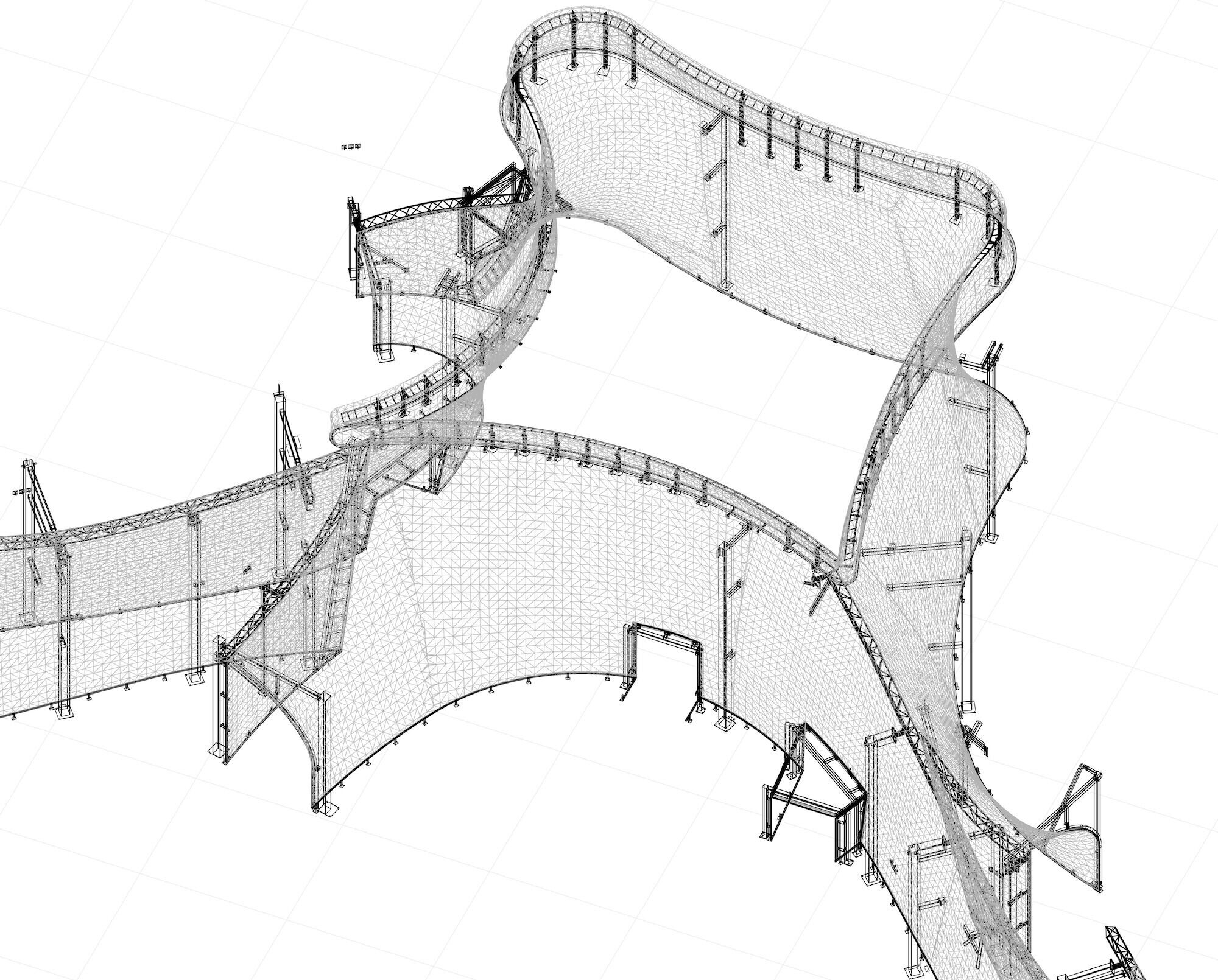

The use of tensile structure techniques provided many advantages for designing large, undulated walls. Given the complexity of the building, the lightness and greater flexibility of this type of structure made it possible to produce a biophilic architectural gesture, a skin, which presents a multitude of shapes and geometries that envelope the different ecosystems, while adapting and integrating in a sensitive way with the original building’s exceptionally complicated structural engineering and mechanical elements. The architectural membrane used in the project is non-stretchable, thus great precision in the design of all the structural elements and the membrane was of utmost importance to avoid any kinks. The tensile membrane shapes were developed to ensure that the tensile fabric surfaces never conflict with existing or projected walls, structures, and mechanical elements. Additionally, this specific membrane possesses acoustical properties that minimize reverberations, thereby improving the comfort level within the space.

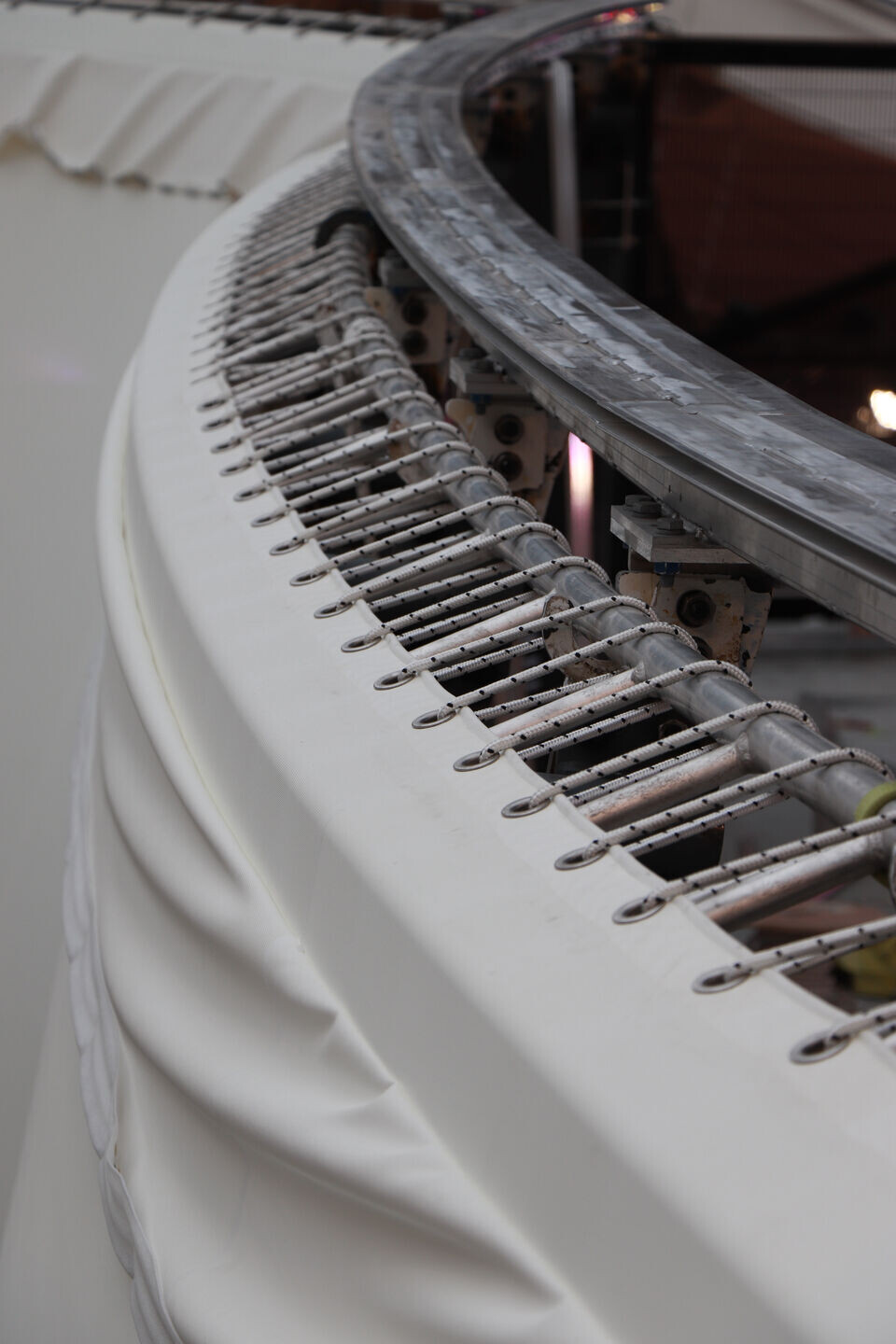

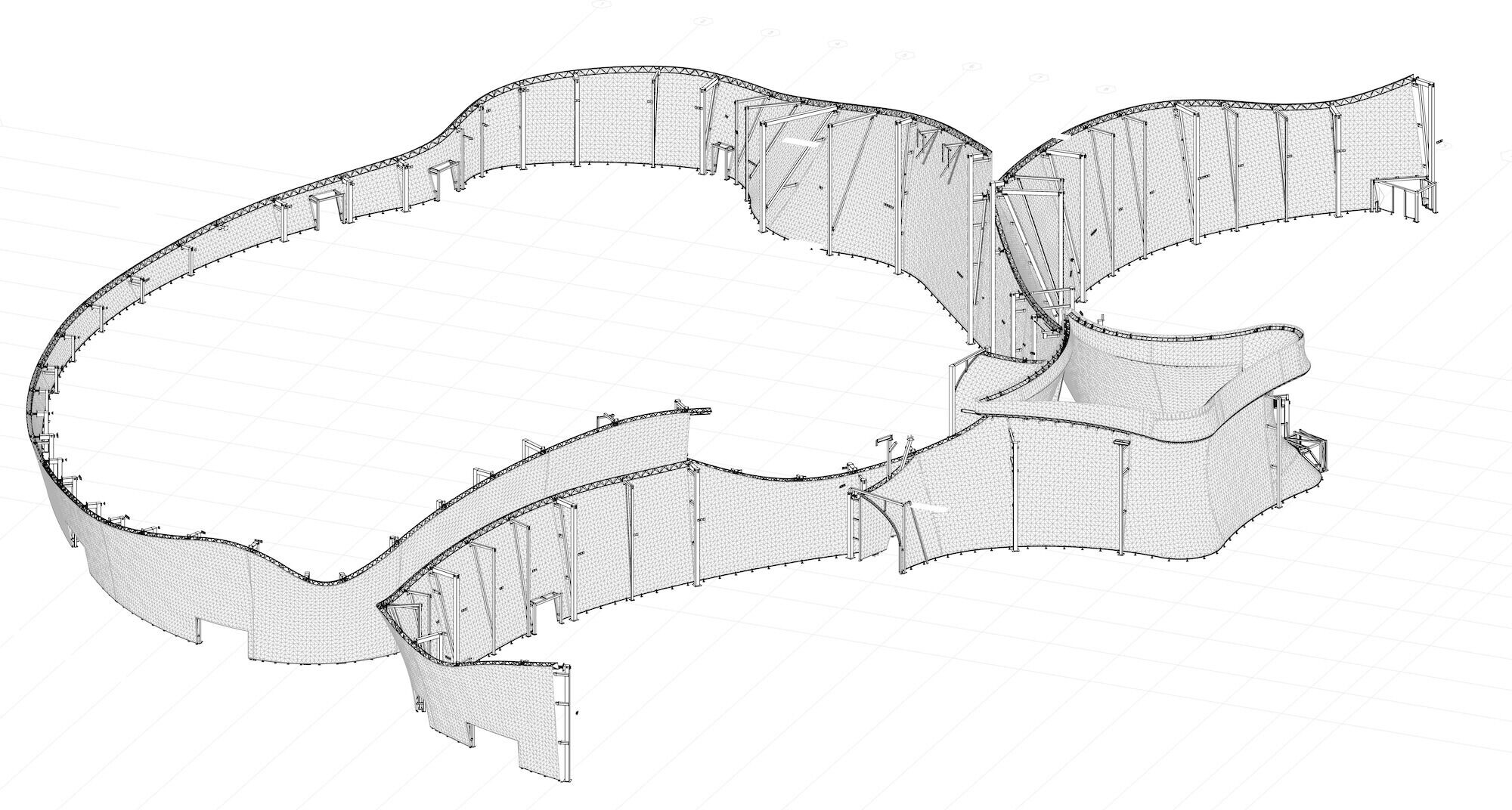

Each section of the tensile fabric walls is unique, with scalene triangular truss beams curving in all directions at the top of each section, shaping the textile surfaces. The non-repetitive nature of the structure called for the separate design and fabrication of each and every element of these truss beams. Raising the bar on the discipline, and rendering the seemingly impossible possible, Sollertia developed a series of unprecedented membrane panels measuring up to 60’ x 60’, which had to be custom-formed to perfection with no room for error. Through a delicate balance of tension, cantilevering, and triangular suspension beams, the Sollertia team curved and tensioned the skin across steel and curved aluminum structures, using mechanical junctions to facilitate a variety of movements and on-site adjustments. Based on the initial design imagined by the architects, Sollertia carried out 3D modeling and researched shapes for the textile membrane panels in order to closely match their vision with that of the client. Sollertia also performed an accurate analysis of the loads in the membrane panels to facilitate the design of adequate rigid structural systems.

Along the way, everything covered by the membrane panels came into play, requiring extremely precise design and manufacturing specifications to accommodate ventilation systems, doorways, sprinklers, electrical outlets, and more. The finished product, measuring approximately half a kilometer in length, and rising nearly four storeys in height, is a visually stimulating contribution to the unique atmosphere of the Biodome.

“We were faced with several challenges simultaneously on this project, including the very complex organic shape of the walls, the many obstacles of the original building to be integrated or bypassed, the various adjustment systems developed and the strategy of the installation sequences,” notes Mr. Le Bel. “In the end, it was a tremendous success that validates our firm’s experience and expertise, and part of its legacy will be that it is one of the first major applications of interior tensile fabric in Montreal.”

Lessons learned

For Sollertia, the Biodome project was a laboratory in motion, inspiring the firm to innovate its discipline through a series of new products and processes that further distinguishes the firm within the textile architecture space. In response to the complex shapes of the textile structures, Sollertia pushed the limits of their specialized engineering software for the design, analysis, and fabrication plans of tensile membranes. The firm also developed new methods and tools for installing large membranes in complex environments as large as 100’ x 100’.

The Biodome is a good example of a project where architectural membranes were used for all of their wonderful inherent properties. The flexibility of the membrane allowed it to fully espouse the architectural concept, and its lightweight structural properties allowed a reduction in the quantity of materials used. That combination makes it a sensible choice for the environment.

“The tensile fabric walls of the Biodome are a great example of the type of project we’re passionate about, and involving ourselves with projects that are carriers of messages that awaken human consciousness and promote environmental awareness and well-being is our priority,” adds Ms. Lortie. “Since this type of construction is not well known, it was important that everyone involved in the revitalization of the Biodome understand the importance of integrating the walls of tensile membranes, and KANVA did an amazing job raising awareness and mobilizing all the teams around this innovative project.”

Team:

Architects: KANVA

Project managers: Marie-Claude LeBlanc (Sollertia)

KANVA

Jean-Sébastien Gariépy (Groupe Unigesco)

Design team (fabric wall): KANVA

Sollertia : Nathalie Lortie, Claude Le Bel, Philippe Gravel

Fabric architecture: Sollertia

Membrane analysis: Jerome Noel (Sollertia)

Curved structure and main structure consultant: Jean-Philippe Major (Conn-X)

Main supporting structure: Alain Déom (NCK Inc.)

Fabrication: Sollertia (membrane); Entreprises Rym (curved tensioning system); Industrie ACL (curved beam); Acier St-Denis (main structure)

Installation of fabric wall: Sollertia

Membrane: Alphalia AW Silent

Membrane manufacturer: Serge Ferrari

Photographers: Olivier Le Bel et Mahnaz Nikbakht – Sollertia; James Brittain; Marc Cramer