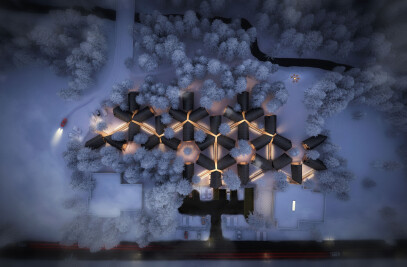

Camp Victory was a temporary exhibition space showcasing Nike innovations during the 2012 U.S. Olympic Trials track & field competition. A series of three pavilions were installed for ten days at Hayward Field at the University of Oregon. The first Eugene Olympic Trials were held in 1972. Adjacent to the field Nike Camp Victory was a temporary highly interactive 150’ x 80’ playground. Inspired by the visualization of speed a network of fabricated tensile pavilions and tracks responded to the mission of experiencing how fast is fast.

The visualization of kinetic energy took the form of explosive triangular pavilions, three stories in height, sheathed in a light-weight translucent poly membrane. Like a sprinter coming out of the starting blocks, the pavilions lean and cantilever, stretching to their structural physical boundaries. The steel-framed pavilions are a hyper-light translation of the posture and tectonics of speed. Intersecting running track lanes connect the pavilions in a geometry of unfolding and refolding of space. Digital media is an immersive thread throughout the site, a result of a highly collaborative design process between the architecture and digital media development.

The three interactive pavilions are each 1500 square feet expressing the spirit of Nike products built on economy of means. The Speed Tunnel exhibit tracked in realtime athletes in motion displayed on a continuous LED screen wall. Another pavilion featured two new Nike footwear technologies Knit and Lunarlon. The third pavilion connected runners through a game of human powered treadmills recording distance and speed to compete for the leader board.

The geometry of the structural frame and the patterns of fabrication for the fabric skin were deliberate, creating pavilions engineered for maximum material efficiency. The design responded to the use of cutting-edge technology--such as the tensile integrity of the Flywire pattern, the dynamic qualities of the Lunarion foam and other high-performance fabrics integral to some of Nike’s product innovations and relating to the material choices for the pavilions. Taking cues from engineered sails used in boat racing where efficiency of both material and form drive performance, the pavilions are skinned in a fabric with high tensile strength to express hyper-lightness and performance. The membrane enclosures are simultaneously transparent and reflective: transparent to reveal the lightweight steel structure, and reflective to allow the pavilions themselves to transform under changing lighting conditions and viewing angles.

Leave no trace on the existing soccer field was the final design objective making the fine balance of the weight of structures critical. At the end of the ten-day Olympic Trials when the structures were disassembled, regular soccer games were back in full force on the same field with no trace of the event.