The 318 meter high Aspire Torch Tower is the design landmark of the Asian Games 2006 in Doha, Qatar. The tower is designed to resemble a large torch, which is received with wire mesh elements supplied by HAVER & BOECKER. The façade consists of 3452 single elements with a total area of appr. 30,000 square meters.

Throughout the facade LEDs have been installed within the mesh to create user-defined effects in varying colours. IMAGICWEAVE® a combination of metal wire mesh and LED technology designed by Haver & Boecker, provides the possibility to broadcast videos on one area of the tower.

At the bottom the Aspire Tower has a diameter of appr. 70 meters. Towards the center it reduces to appr. 27 meters. The maximum diameter at the top measures around 45 meters. The construction time of the tower was just 15 months (excluding interior finishing).

The architectural brief was to create a similar transparency in each part of the tower from one viewing point. This was achieved by increasing the opening progressively from bottom to top. By using different opening sizes the transparency can be adjusted to construction conditions accounting for different viewing distances and perspectives. Even with extreme angles such as 5 degree (looking up from the bottom) the larger open area in the top part of the tower still offers transparency in the mesh. Different viewing angles let the mesh appear similarly open over the full height creating a homogenous facade.

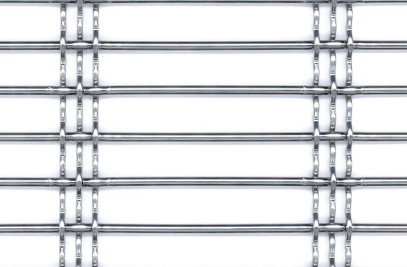

Using the wire mesh type DOGLA-TRIO it was possible to vary the clear openings of the horizontal wires between 14 and 44 mm. The open area was incrementally increased from 72% to 85%.

The vertical wire groups of DOGLA-TRIO consist of three specially preformed wires. HAVER & BOECKER ensured, that these wire groups run in one continuous line from element to element across the full height of the tower. The standard elements are 8 meters high with a maximum width of 1,96 meters; special elements are as long as 13 meters.

Utilising the trapezoidal form for all elements, the wire mesh can clad circular buildings of varying diameters such as the Aspire Tower. The polygonal layout makes the facade appear circular without the requirement for costly panel form bending.

The mounting system was developed by HAVER & BOECKER and coordinated with the facade planners and metal contractors. At the top each mesh element is equipped with an open hook strip, which creates an L-Profile when hung on-site. The bottom part of the panel has a flat tension profile with clevis screws and pressure springs at appr. 200 mm centers, which allow for individual tensioning of each element. To reduce deflection and inherent vertical loadings, each element is connected in the center to round tubes behind the mesh using wire connectors.

HAVER & BOECKER supplied ready-to-install mesh panels direct to site, where they were tensioned into frames in a specially built manufacturing hall. As a final step, the frames were lifted to their final destination on the facade, where they were connected to the structure of the tower.

Due to the tower’s height and exposed location, extreme standards for noise emission and windloads were required. The effectiveness of wire mesh for such projects was proven by means of various tests in a wind tunnel.

HAVER & BOECKER IMAGIC WEAVE® Integration of LED-Techniques into wire mesh facades.

The combination of LED technology and woven wire mesh enables the creation of many distinct lighting effects including full video presentations. The special integration of the LED diodes into the wire mesh ensures that the visual aspects of the facade are not disrupted by interfering profiles: The homogenous appearance of the facade is maintained at all times, even when the LED’s are not in use. Additionally this type of attachment offers an easy replacement of single LED strands as required during maintenance.

An 8 meter high section of the tower below the swimming pool has been equipped with the IMAGICWEAVE® system. The LED area is separated into three high-resolution video screens of 15 m x 8 m and three fields of 35 m x 8 m with a lower resolution, where logos or advertisements can be created. The density and number of LED diodes pre-determines the resolution and quality of the video screen.

For certain mesh types existing facade or wall claddings can be retrofitted with the IMAGICWEAVE®system.

During the Asian games, three high resolution video screens are being utilised for Games Summaries, news and advertisements. Even live broadcasts are possible at all times.

With its’ many technical innovations the Aspire Tower has become a monumental building for the Region, enhancing the pride & esteem of the Gulf State of Qatar.