Swiss-based global building materials and aggregates company Holcim has launched Phoenix, a pioneering and circular 3D printed concrete bridge. Built in partnership with the Block Research Group (BRG) at the Institute of Technology in Architecture at ETH Zürich, Zaha Hadid Architects Computation and Design Group (ZHA CODE), and incremental3D, Phoenix demonstrates the interplay between low-carbon and circular technologies in infrastructural development.

Launched at Holcim’s recently inaugurated innovation hub in Lyon, France, Phoenix demonstrates an approach to innovative and sustainable building solutions. The project is an evolution of Striatus, an earlier 3D printed concrete bridge developed by Holcim in partnership with BRG, ZHA CODE, and incremental3D — Striatus was unveiled at the 2021 Venice Architecture Biennale. Phoenix is built using ten tons of recycled materials, including recycled aggregates from the original blocks that made up Striatus. (Hence the name Phoenix, as it rises from the ashes of Striatus.)

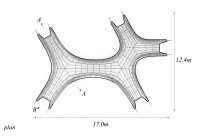

By employing computational design and 3D printing, circular construction reduces the amount of material used by up to 50 percent, with no compromise in performance. With a length of 17 meters (approx. 56 feet) and a width of 12.4 meters (approx. 41 feet), Phoenix stands entirely through compression and is assembled without mortar or reinforcement.

The bridge’s carbon footprint is also lower and the design utilizes Holcim’s proprietary ECOCycle® circular technology. The company explains: “We developed a custom concrete ink for Phoenix, integrating recycled construction demolition materials with a 100 percent recycled ECOPlanet cement.” (ECOPlanet is a low-carbon cement range with a CO2 reduction of around 30 percent.) Phoenix’s CO2 footprint is 40 percent lower than that of Striatus and its overall carbon footprint is 25 percent lower. This is also in part due to a decrease in the reliance of single-use materials for falsework (a temporary framework) during construction.

Phoenix is designed as a permanent structure, unlike its predecessor (however, the bridge’s circular design ensures its blocks can be disassembled and recycled). BRG explains that “its shallower geometry eliminates the need for steps, making it more accessible and functional for pedestrian use. The bridge also features a handrail system elegantly held in place by the thrust in the balustrade arches.” Describing the precise assembly of Phoenix, BRG adds: “Modular falsework components were developed that integrate a minimal timber waffle structure with standard, reusable, off-the-shelf steel beams [thereby minimizing] the volume of single-use timber elements. Three to six 3D concrete-printed blocks were precisely assembled on each falsework module before being lifted on pre-installed scaffolding towers.”

“Phoenix is a significant milestone in technology readiness [and] showcases the maturation of integrated design to construction technologies that were initiated with Striatus,” says ZHA CODE. With numerous improvements, from the robustness of the digital design tools to better integration with robotic concrete printing parameters, "production was almost double the number of blocks in less printing time.”

With the completion of Phoenix, Holcim and its partners are now exploring how to scale up the project in order to provide more generalized and sustainable infrastructure solutions.